Retrofitting Dampers is SV-SHOCKS’ solution to minimise lifecycle costs. As fleets age, maintenance costs rise but a full replacement is not always the only solution. With decades of experience, SV-SHOCKS has proven that replacing old dampers with newly engineered retrofit solutions delivers significant benefits across multiple industries.

In many projects, customers have provided nothing more than a worn-out damper as a starting point. Without drawings or specifications, SV engineers carefully analyse the used component and design a brand-new replacement that matches the original performance but with modern materials, tighter tolerances, and longer service intervals.

Industries We Serve

Rail vehicles – Passenger & freight retrofits.

Heavy trucks & buses – Long-haul durability.

Military vehicles – Battlefield-tested.

Agricultural machinery – Field-proven strength.

Industrial equipment – Continuous-operation resilience.

Why SV’s Retrofitting Makes Sense

Lower lifecycle costs

New SV dampers reduce wear on bogies, minimise maintenance needs, and extend overall service life. Worn or poorly functioning dampers generate vibration, uneven loading, and costly repairs or downtime.

Applicability across industries

Retrofitting is not limited to one damper industry. SV provides similar solutions for rail, heavy trucks, military vehicles, agricultural machinery, and industrial equipment. All operating in extreme environments of heat, cold, moisture, dust, or vibration.

In-house competence

When SV engineers create a damper based on an existing component, there is no need to rely on special OEM parts or drawings. In-house production and a wide product portfolio ensure fast, reliable delivery.

Meeting Safety Regulations

In most industries, safety regulations strictly require that any replacement part corresponds exactly to the properties of the original. Before installation, the operator must approve the retrofit component to ensure compliance with safety standards and operational requirements.

SV-SHOCKS follows this principle rigorously: replacement dampers are engineered to meet or exceed the original specifications, and the entire manufacturing process is carefully documented to demonstrate full technical equivalence. This ensures that every retrofit damper not only fits perfectly but also provides the same (or improved) performance and safety characteristics demanded by regulators and operators.

SV-SHOCKS ensures compliance:

- Dampers are engineered to be technically equivalent to the original.

- The manufacturing process is fully documented to support regulatory approval.

- Every retrofit is delivered with clear specifications and test data.

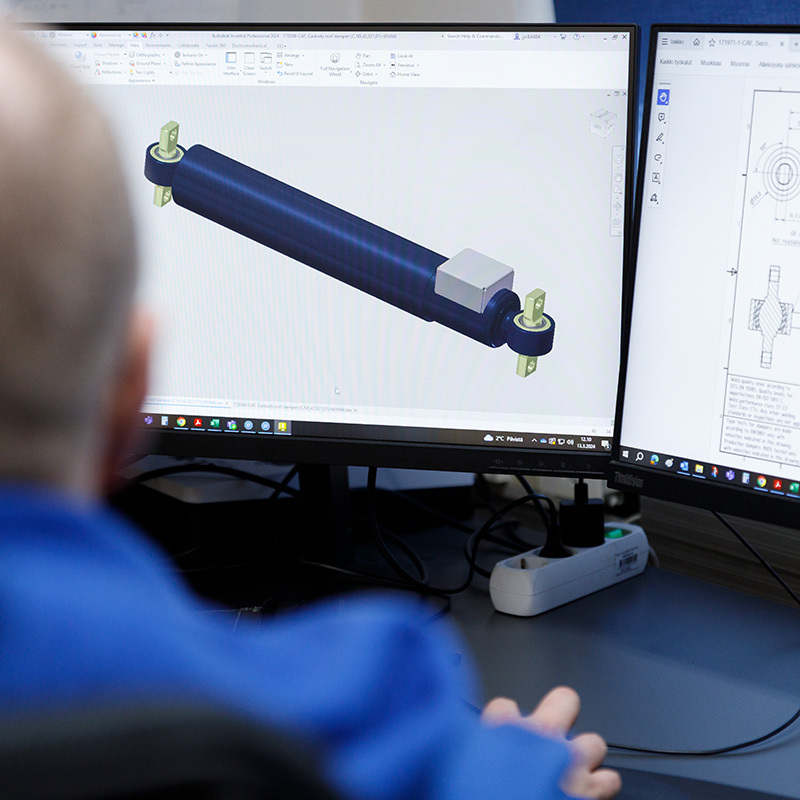

The SV Approach to Retrofitting

At SV-SHOCKS, every retrofit project is an opportunity to cut costs, extend equipment life, and improve operational reliability. Whether starting from a drawing or from a worn-out part, SV engineers ensure that a new damper gives machinery and vehicles a new lease of life.

Assessment of the old damper

Wherever possible, the product is designed based on existing drawings. If no drawings are available, SV engineers measure and analyse the worn component to define the required specifications.

Design & material selection

Modern materials, advanced seals, and hydraulic fluids are chosen to outperform the originals and withstand extreme conditions.

Manufacturing & testing

All dampers are produced in SV’s own facilities and tested under simulated real-world loads before delivery. Every damper is tested up to -60°C and also for extreme heat.

Operation & maintenance

Retrofit solutions come with extended service intervals, clear documentation, and the assurance of durability in the harshest environments.

Proven Performance in Extreme Environments

Cold climates – Reliable function in Arctic temperatures.

Hot climates – Resists heat stress in desert operations.

Salty environments – Corrosion-resistant materials for marine or winter use.

Uneven terrain & vibration – Designed for high loads, resonance control, and stability.

Sustainable long-lasting shock absorbers

We strive to offer sustainable, recyclable and environmentally friendly solutions. Our goal is to conduct long-term, profitable, ethical and responsible business, taking into account our financial, ecological and social responsibility.

Retrofitting shock absorbers is one solution to minimize life cycle costs. New SV dampers reduce wear on bogies, minimise maintenance needs, and extend overall service life.

The ultimate performance and long service life

SV-SHOCKS production and design skills enable us to produce a large variety of railway dampers in large or short production runs.

We can manufacture shock absorbers for every purpose, ensuring that the specific requirements of all customers are met quickly and efficiently. SV-SHOCKS is committed to the delivery of reliable products to the market.

SV-SHOCKS has a broad industry experience and a worldwide reputation for reliable and long-life products, meeting the needs of even highly customised applications.

Drop us line and we’ll get back to you

As a flexible manufacturer and a pioneer in valve technology, we are able to manufacture customized products according to local needs.

How we can help?

Mikko Vesanto

Sales & Deliveries

+358 45 6575686

mikko@sv-shocks.com

Markku Hirvi

Sales Manager

+358 45 6578544

markku@sv-shocks.com